Small Parts – 158 Secret Pieces That Hold a Boardy Together

At first glance, a Boardy looks simple. Yet beneath those few obvious larger parts, it hides an impressive 158 small parts (screws, bearings, washers, springs, etc.), all perfectly working together. Every tiny piece has a purpose and a place.

Each unit is assembled by hand, one step at a time. Most of these parts are stainless steel, and some of them are custom-made exclusively for the Boardy in our CNC workshop, and many are secured with torque and thread-lock for lasting precision. It’s not fast work, but that’s the point.

Every bolt, bearing and drop of thread adhesive adds up to something you can trust for years. The result is a premium kick scooter that feels solid, silent and smooth from the very first ride.

Why so many small parts?

We never wanted to fuse everything into a handful of complicated, unrepairable components. Our approach reflects sustainable manufacturing: small-batch production, durable materials, modular and repairable design instead of throwaway shortcuts. The wooden frame of the Boardy behaves like a living structure: it flexes, absorbs and returns to shape. Each joint and bearing plays its role in that quiet balance.

When everything fits as it should, you feel it. The smooth glide, the quiet confidence, the sense that nothing strains or rattles. Most riders will never think about those 158 small parts inside. And that’s fine. They’ll simply feel the difference.

Even More Small Parts Photos

Sustainable Product Design in Practice

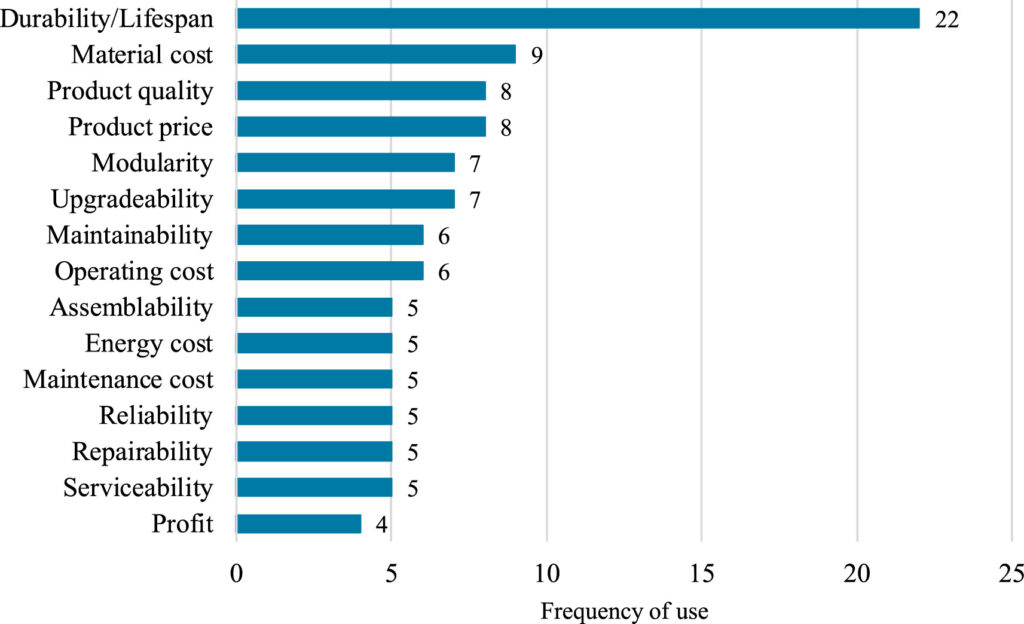

The thinking behind Boardy’s modular build aligns closely with modern sustainable product design theory. A research in the Journal of Cleaner Production (“Sustainable product design factors: A comprehensive analysis“) shows that durability, modularity, maintainability, and repairability consistently rank among the most influential economic factors in sustainable product design. These principles highlight that long product lifespan, easy upgrades, and replaceable components reduce waste, lower costs over time, and deliver greater long-term value for users.

According to this comprehensive analysis, durability and lifespan were the most frequently cited factors across the literature, followed by material cost, product quality, product price, and modularity — all central to Boardy’s philosophy. Modular, repairable design avoids fused, disposable parts and supports lower lifetime operating costs. This aligns with a broader shift toward life cycle–oriented product design, where each small part contributes to a more sustainable whole.